Work smarter, not harder. A very simple saying but it is true. The smarter you work the easier the projects will come and the quicker you can get projects done. Here are some tips and tricks to help you boost and skyrocket your efficiency every day in the work shop.

Always Make Sure Your Blades are Sharp

Having a dull blade can make cutting very difficult and extremely frustrating.

Dull tools such as chisels, blades, planes, and scrapers don’t cut nearly as cleanly as sharp tools. They tear at the wood fibers resulting in a fuzzy, uneven, unprofessional look.

Tools that have been chipped or nicked require grinding. Here at 612 Milling, we use a bench grinder, wet grinder, or even a belt sander can be used in some situations. The easiest and quickest way is using a bench grinder. Just make sure your wheels are in good shape and clean.

Using a bench grinder can heat up a tool quickly. The best way to avoid this, is to have a bucket or pan of water next to you. Once it starts to get warm/hot, dunk the tool in the water.

Tools with sharper blades make woodworking easier, more efficient, safer, and less infuriating.

Keep a Clean and Organized Shop

To optimize you time and energy, clean up your mess every day. Nothing is worse than searching for a tool, or bit, or anything else in a dirty and messy shop. Another tip is only keep out tools that you use every day. This way you’re not spending your time putting things away you know you’re going to use the next day.

Marking Cut Lines

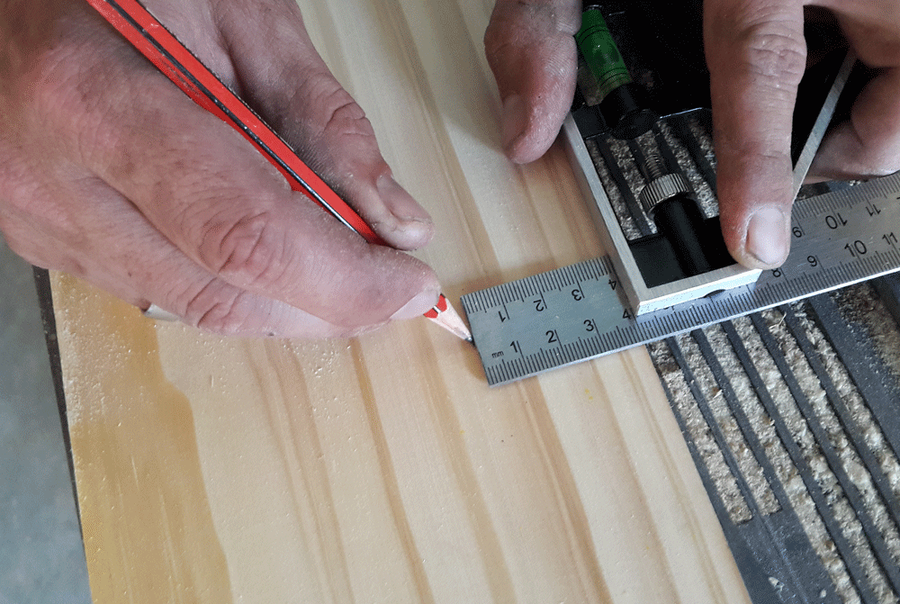

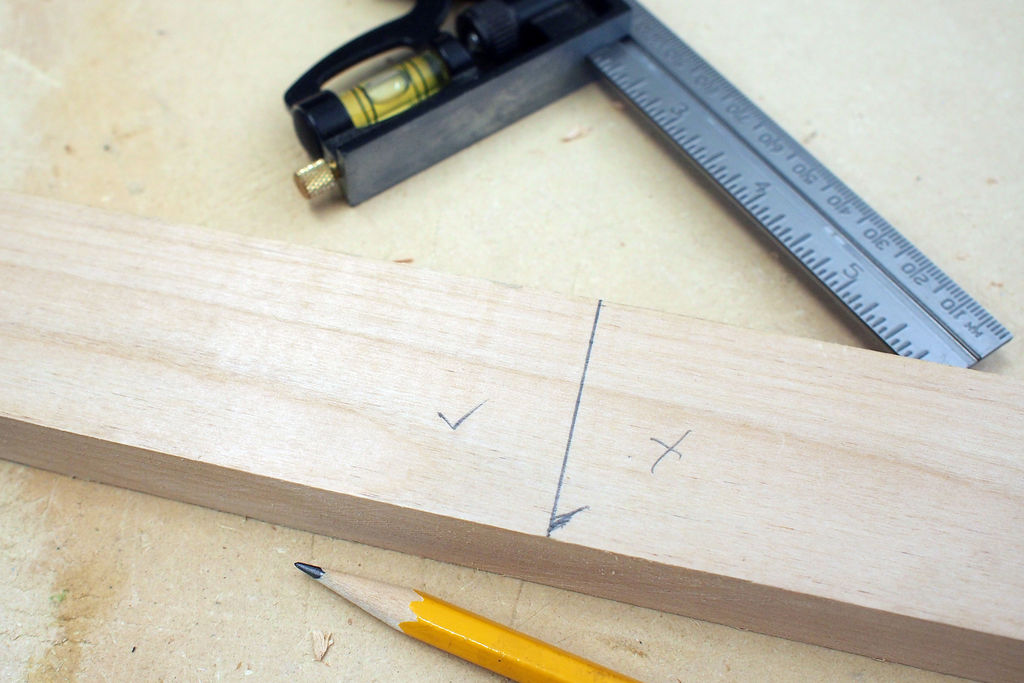

When measuring material to be cut I find it helpful to put a little tick mark of the side to cut on. This simple action saves countless time remeasuring and helps me account for Kirf, the thickness of the blade you are cutting with.

The solution is to measure your piece and make a small tick to one side of the measured line, indicated which side to cut on. Once measured, line your blade up to the line with the blade on the ticked side, so that the kerf will be on one side of the line and not into your measured area. If you ever work with a buddy and are dividing labor this is a great trick to keep each other informed of the areas to cut.

I use this every time I mark cut lines, and it’s a great habit to fall into.

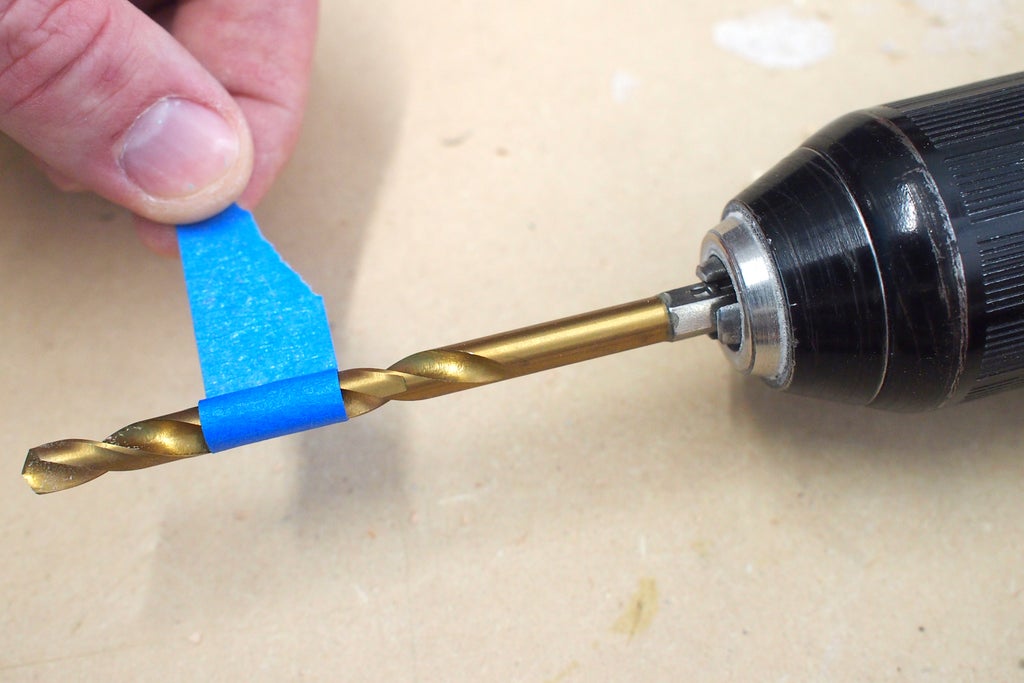

Drill Depth

Sometimes when you need a hole drilled through the material, it doesn’t always go completely through the material. If you are using a drill press, it is fairly simple to set up a press stop. I would highly recommend using a drill press in any situation that is available. If a drill press is not available, then you can you and handheld power drill. Use a piece of tape to mark the intended depth of the hole and only drill down to the tape marker.

Always Use a Brush

Use a brush after you are done cutting especially if you are cutting metal. Metal shavings can scratch and cut materials. This also goes back to having a clean workshop.

Sand Paper Organizer

You can either use a file organizer or make your own organizer. But it is a lot easier to find the right grit you are looking for if everything is organized. The picture below is an example of a high end organizer but you will not be disappointed in them. Mark what each shelf is according to the grit. Another option that I have used, is using a nail or screw in the shop wall and hang the sandpaper on the nail or screw. On each nail or screw, separate each grit. This is a very simple and cheap way of organizing sandpaper.

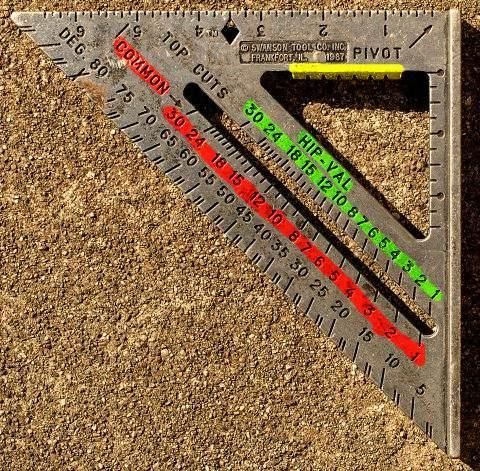

Know How to Use a Speed Square

Your speed square has a lot more tools than people realize. For example, a perfect scribe, angles, pitches, etc. I will have another post about this more in depth. A couple of ways you can use it for is a saw guide, marking angles, squaring lines, and scribing lines.

Conclusion

Use these options to help you in the workshop. These small tips and tricks will help you save time and hassle in the future of your workshop. I would love to hear what types of tricks you use.

Comments

Let us know if we missed anything or have any questions. I am willing to add more sections that you think should be in here. Drop a comment! Looking forward to hearing from you!

Make sure to follow us on Facebook and Instagram!